Highly Recycled Asphalt Pavement (HighRAP)

Objective

The objective of the HighRAP project was to develop recommendations that would allow increasing the average reclaimed asphalt content in asphalt production without compromising the pavement performance.

Duration: 04.07.2019-31.12.2022

Project Summary

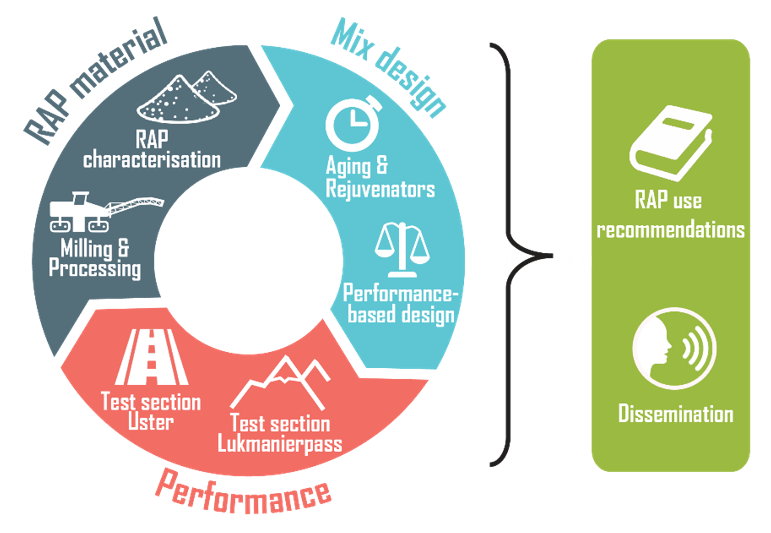

The project addressed three main research topics:

1) RAP Materials

2) Mix design

3) Performance

Within these topics, individual studies addressed the characterization of RAP, improvement of RAP crushing and screening, aging and rejuvenator selection, performance-based mixture design, and construction of two test sites with high RAP content: one in a high traffic road and one at high altitude (1,900 m above sea level).

Project Activities

The HighRAP project tasks and activities for each of the three research directions are shortly summarized below.

|

Study |

Tasks |

Activities during HighRAP project |

|

RAP milling & processing |

Develop RAP processing procedures that allow maximizing the RAP use in production. |

|

|

RAP characterization |

Develop simplified test methods for rapid RAP characterization without extracting binder. |

|

|

Aging & Rejuvenators |

Develop an aging protocol for mixture design to assess durability of rejuvenated RAP. |

|

|

Performance-based mix design |

Develop of a procedure that would allow designing high RAP mixtures with similar performance and life cycle to the conventional asphalt. |

|

|

Test section in Uster |

Evaluate full-scale production and paving of high RAP mixtures for high traffic roads. |

|

|

Test section in Lukmanierpass |

Evaluate full-scale production and paving of high RAP mixtures for high altitude roads. |

|

Publications

|

Project report |

|

|

One-page summary |

|

|

Summary (11 pages) |

|

|

Presentation |

|

|

Calculation tools

|

|

|

Scientific publications |

|

|

Press |

Videos

Project Leader

Team

Lily Poulikakos, Empa

Lukas Boesiger, Ammann Schweiz AG

Bernhard Kunz, BHZ AG

Henry Mazzoni, Catram AG

Peter Bruhin, Catram AG

Dominique Lötscher, Reproad AG

Urs Schellenberg, Kanton Zürich

Chair

Fabian Traber, Bundesamt für Strassen (ASTRA)

Members

David Hiltbrunner, Bundesamt Für Umwelt (BAFU)

Remo Fehr, Amt für Natur und Umwelt - Kanton Graubünden

Dominik Oetiker, Amt für Abfall, Wasser, Energie und Luft – Kanton Zürich

Christoph Gassmann, Baudirektion Kanton ZH Tiefbauamt

Nicolas Bueche, Bern University of Applied Sciences (BFH)

-

Share